SLA Printing

Amazing results do not always come easy. Higher printing costs are due to more expensive materials compared to FDM, and the amount of post processing required. After every print is finished, supports must be removed and sanded by hand to remove any traces. Then the print is bathed in an IPA bath to removed left over resin. Finally, the print is UV cure anywhere from 960 to 90 minutes to cure the resin and provide a strong print. SLA is best for prints with fine details.

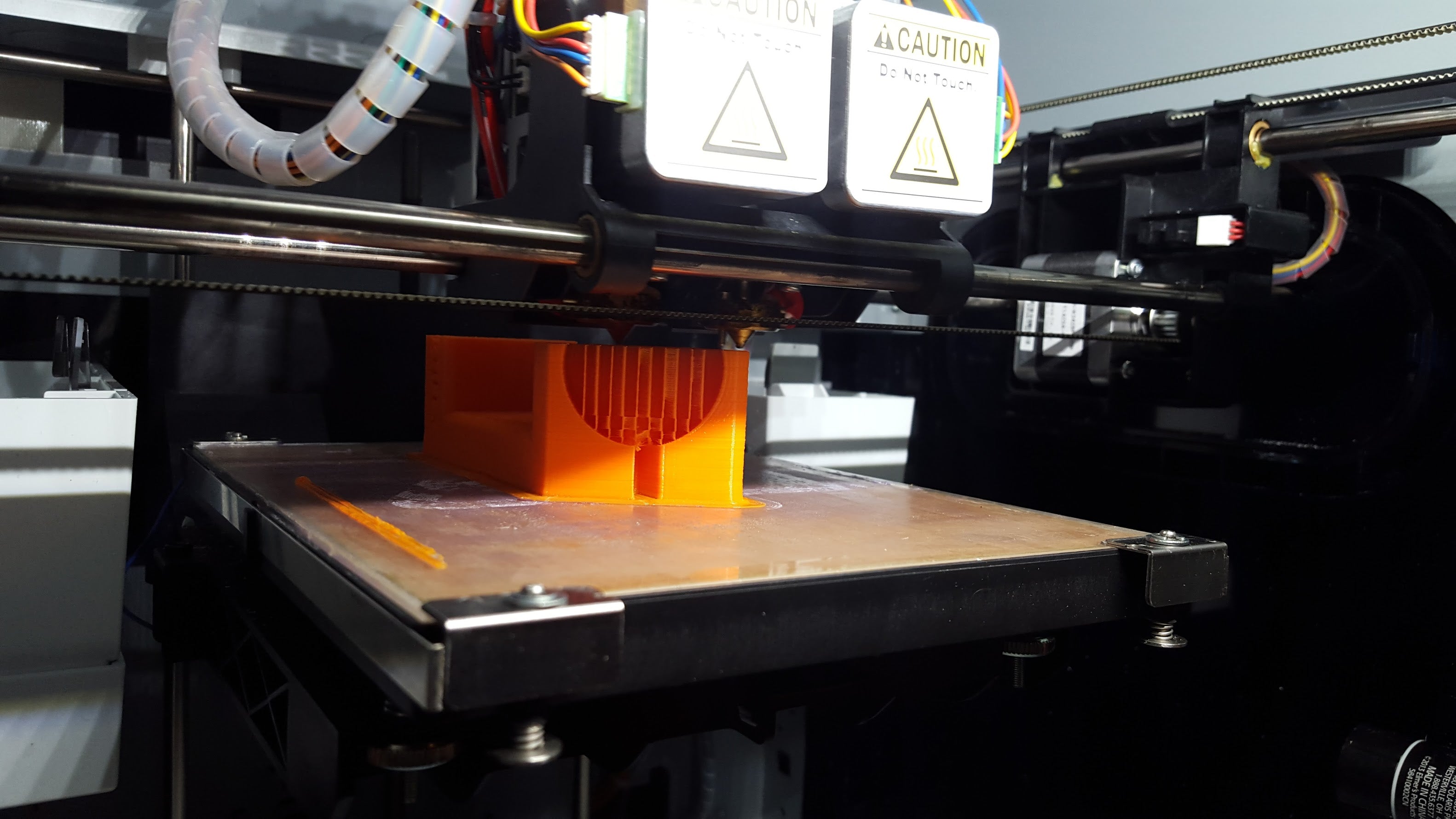

FDM Printing

This is the printing style when most people refer to 3D Printing" as this method is the most popular, and also the best value. Layer lines will be visible and parts can feel light depending on their infill setting. Parts are generally easy to print and post process. Most supports can be snapped off by hand, or bathed in a vat of water for water soluble support removal. FDM can also struggle with fine details and surface smoothness.

ABS FDM

• Reliability, stiffness, strength, impact resistance, higher dimensional stability and chemical resistance

• Excellent impact resistance

• Good stiffness and tensile strength

• Good chemical resistance

ASA FDM

• Similar mechanical properties to ABS but superior UV and weather resistance

• Commonly used in outdoor applications

• UV resistance

• High impact and wear resistance

• High heat resistance

• High toughness

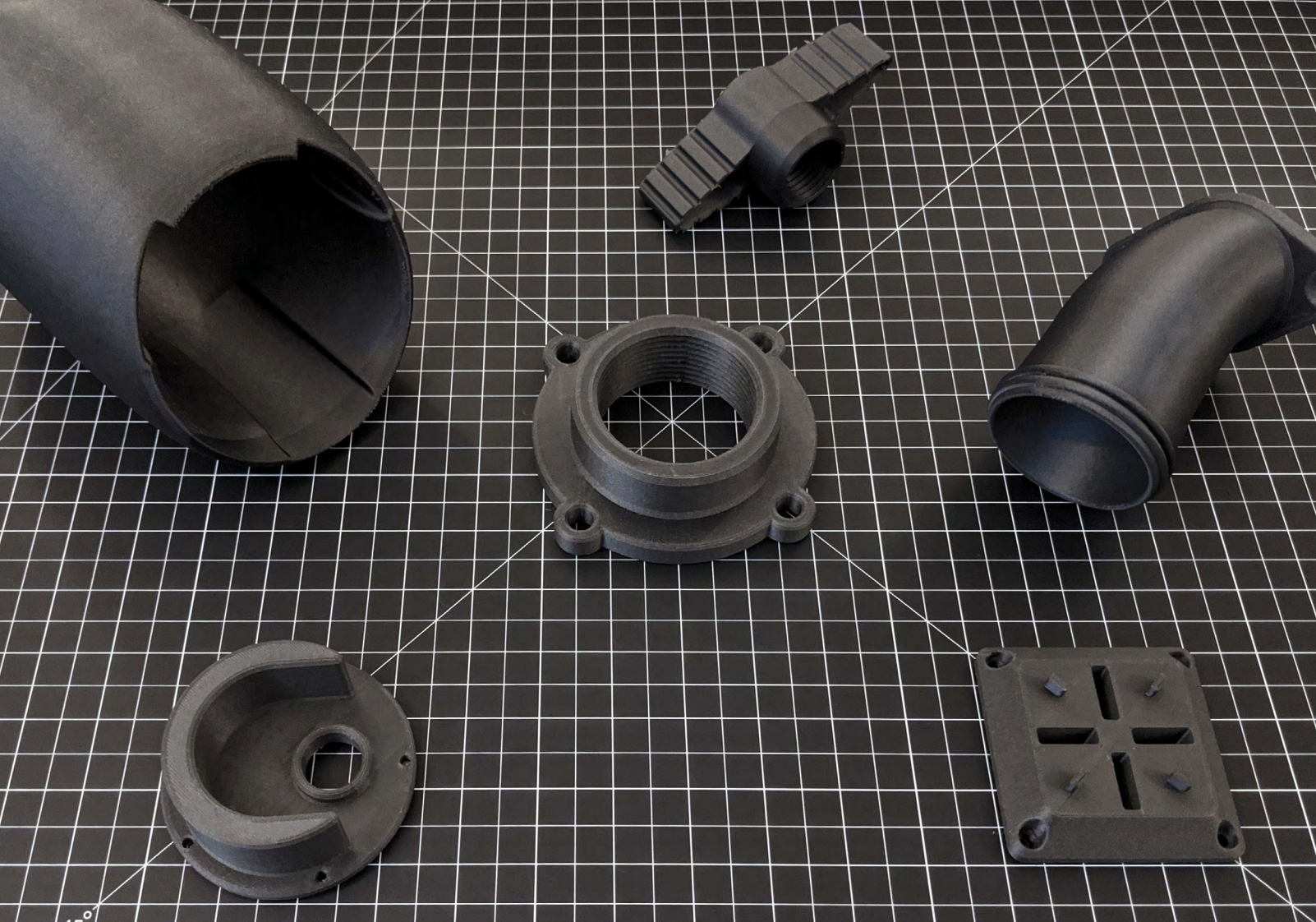

Carbon Fiber Reinforced Nylon FDM

• chopped short carbon fiber in polymer matrix base of Nylon

• High strength-to-weight ratio

• High stiffness

• High dimensional stability

• Lower shrinkage and warpage

• Electrostatic discharge (ESD) property

Nylon FDM

• Outstanding mechanical performance with good toughness, strength, and impact resistance

• Very tough

• Excellent tensile modulus and strength

• Low friction coefficient

PETG FDM

• Strong, durable, with good heat resistance

• Excellent chemical resistance

• Easy to print

• High stiffness and strength

• Good impact resistance

PLA FDM

• Easy to print with excellent surface finish

• Wide range of color options

• High stiffness and strength

• Biodegradable and environmentally friendly

• We have just about every color possible in Genuine Ultimaker PLA

Polycarbonate FDM

• Excellent impact resistance, high stiffness, heat resistance, and flame retardant properties

• 110°C heat resistance

• Excellent impact resistance

• High stiffness and strength

• High toughness

• Flame retardant

• Optical translucency

Polypropylene FDM

• Durable, break-resistant, fatigue-resistant, and semi-flexible

• Excellent durability and toughness

• Chemical resistance

• Food safe

• Lightweight

• Semi-flexible and break-resistant

Flexible TPU FDM and SLA

• Its rubber-like elasticity, resilience, and durability make it suitable for uses requiring impact-absorption and a soft-touch surface

• Elastic and flexible

• Wear and tear resistance

• Durable and resilient

Kimya ABS Reinforced with Carbon Fiber or Kevlar FDM

We stock both reinforced materials for projects where the properties of ABS will not be enough

Formlabs SLA Resins

• Super high resolution and detail

• Can achieve superior surface finished compared to FDM printing

• Wide range of available resins for any project